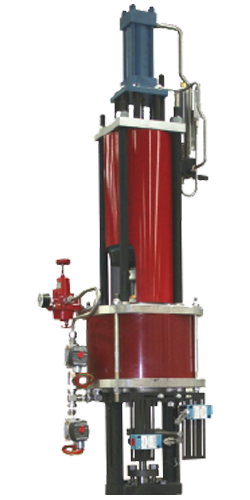

D-Series Control Valves

D-Series (ID) Control Valves are designed for process control systems for food and beverage, pulp and paper, chemical and petro chemicals, boiler feed water and fuel systems controls and packaged OEMs such as heat exchangers, water purification, metal cleaning and deplating.

Features

- High Flow Capacities

- Balanced Plug Design

- Cup Seal Technology

- Class V Shutoff

- Ultra Compact Actuators

Material

Carbon Steel (WCC / LCC), Stainless Steel, Chrome-moly Steel

Size

2" - 16"

Design

Single Seated, Top Entry, Globe and Angle Style With Cage Guided Balanced Plug

Pressure

150 - 1500#

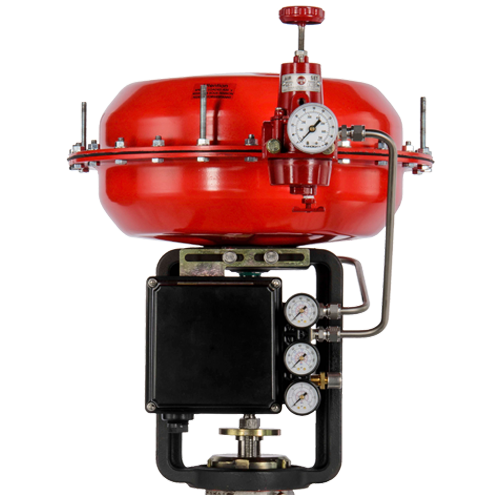

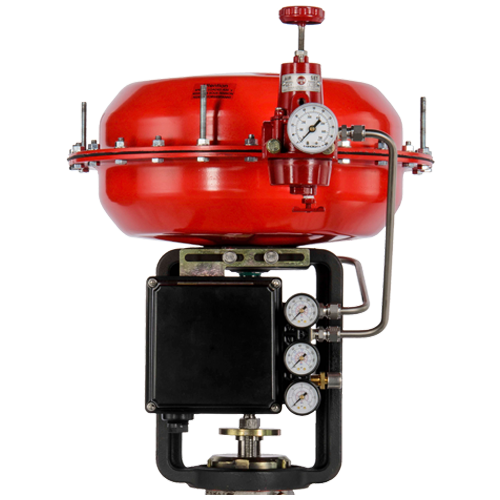

Spring and diaphragm actuators

Spring and diaphragm actuators are rugged high thrust units with flanged yoke to bonnet connections for simple maintenance and better access to stem packing. These workhorses of our control valve lines have been proven and perfected for nearly forty years of in-service usage. They are available in four sizes: 35, 55, 85, and 135 in.

Features

- Compact with strength for quick, accurate control

- Rugged cast iron or aluminum yoke with steel covers for long, trouble-free service

Sizes

35, 55, 85, 135

Material

Aluminum, Cast Iron

Pressure

Max air pressure:60

Levelmatic Liquid Level Pilot Controllers

Applications/Description

Levelmatic pilot controllers use a simple, stable, floatless differential pressure sensing principle. They require only two simple connections to the vessel (open or closed). Standard units come in two sensing ranges: 0 to 36 inches and 0 to 200 inches(H20). Normal operating pressure is 10-22 psi. Static pressure on the sensing diaphragm can be anywhere within the range of 30″ Hg vacuum to 300 psig. Options include fixed or proportional band.

Features

- 3 – 15 Psig Output

- Fixed or Proportional Band

- Bi-Metallic or Liquid Filled Temperature Element

- Single-Loop Pneumatic Controller

Differential Pressure Pilot UDDVP/UDRVP

Applications/Description

UDDV, UDDVP, UDRVP pilot controllers consist of a differential super structure mounted on a standard force balance or adjustable band pilot body. Suitable for differential pressure control, vacuum control, pressure control with remote set point adjustments.

Features

Two separate sensing diaphrams preventing contamination of either fluid in case of diaphram failure.

S Transfer Valve (Shift Loads)

Applications/Description

The S transfer valve is to avoid the problem created when the 2/3 valve begins to take up the load. The transfer valve is a pneumatic device that switches the small valve off, and engages the larger valve. It senses the 3-15 psi pneumatic signal. When the first valve engaged reaches 15 psi, it switches the pneumatic signal to the larger valve.

Features

- Shifts flow between low and high load valves @ 15-25% capacity

- Handles wide load swings

- Eliminates circuit oscillation

- Protects against high velocity erosion of valve

- Reliably maintains steam outlet pressure